WE'RE HIRING! Quantum Design is currently looking to fill several positions with hard-working, dependable individuals.

Print Up To 10MM More Sheets Per Year!

Introducing the New LS Model Inline Roll Sheeter with Lap Splicer

Learn MoreRealize savings with a Quantum Roll Sheeter

Material Savings

Save up to 30% in raw

material cost running rolls

versus pre-cut sheet piles.

Improved Efficiencies

Faster net production

means more output

on the press.

Increased Uptime

Rolls run longer with

fewer press shut

downs to change piles.

Quantum Roll Sheeter products are superior in performance and reliability in the roll sheeter market and are backed by a highly innovative design staff in mechanical and controls engineering. With standard roll sheeter models accommodating press requirements 40” to 81” and everything in between, Quantum provides the best roll sheeter on the market along with the ongoing support needed to insure successful installation, start up and continuing operational maintenance throughout the life of the machine.

Material Savings

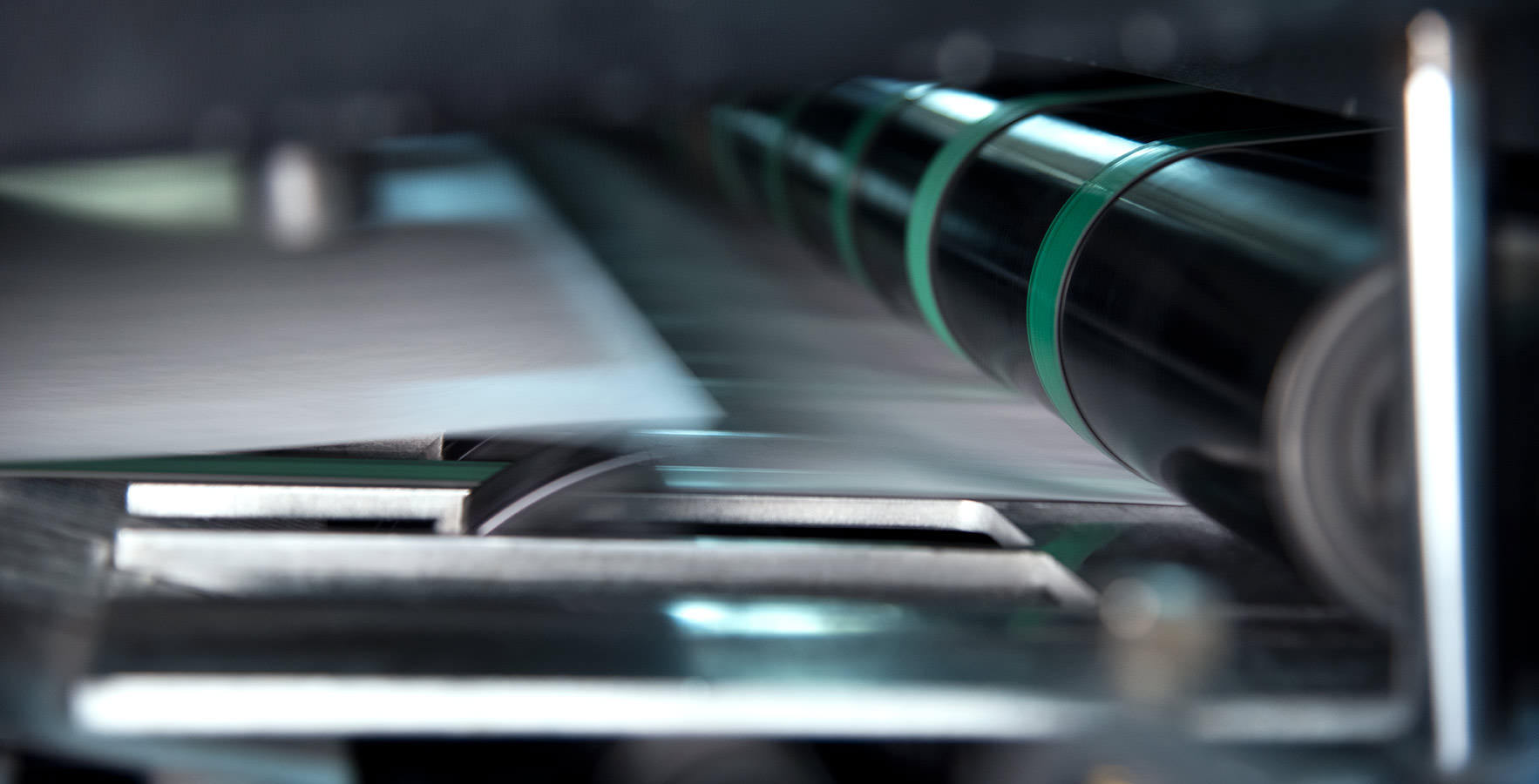

Capable of handling plastics and other synthetic materials with ease

While plastic and synthetic materials present challenges for most roll fed presses the Quantum Roll Sheeter has a proven method of cutting and feeding thin synthetic materials allowing more versatility by using a roll sheeter.

Increased Efficiencies

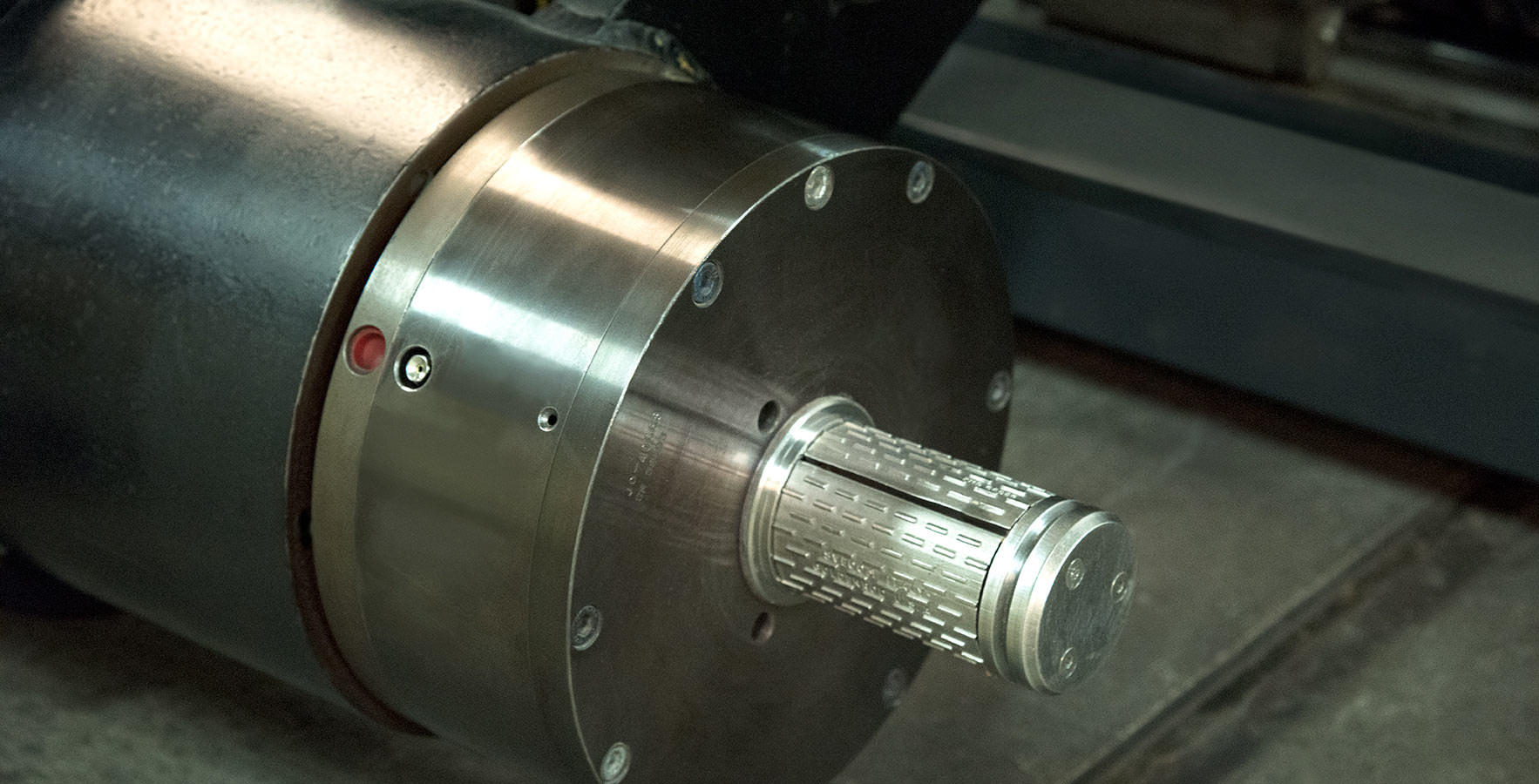

Shaftless roll stands make roll changes faster

The dual arm roll stand allows operators to load rolls without removing heavy core shafts reducing down time and eliminating safety concerns.

Increased Uptime

Advanced Dancer and Web Up Feature

The dancer design allows the operator to feed the web in seconds without ergonomic concerns.